Reverse Osmosis Membrane Material – What Are They Made of?

Written by: Alexandra Uta // Last Updated: Mar 14, 2023

This page may contain affiliate links. If you buy a product or service through such a link we earn a commission at no extra cost to you. Learn more.

At the heart of every RO system lies a reverse osmosis membrane – an ultrafine barrier that removes contaminant particles down to just .0001 microns in size.

RO membranes for home use are made of two primary materials: polyamide composite and cellulose triacetate. Each material has characteristics that give it advantages and disadvantages in environments with different water characteristics.

Let’s take a look at these two membrane materials and how they stack up in real-world use.

Key Takeaways

- Reverse osmosis membranes are made from two primary materials: Polyamide composite (TFC) and cellulose triacetate (CTA). Each material has its respective strengths and weaknesses.

- Cellulose triacetate membranes are cheaper but less efficient in terms of salt rejection and flow rate. They can only be used in a fairly narrow water pH and temperature range. On the plus side, they can handle higher concentrations of chlorine and iron in the feed water.

- Polyamide composite RO membranes are costlier but have higher productivity and lower salt passage. Also, they can tolerate wider pH and water temperature ranges. They are significantly more sensitive to chlorine, which must be completely removed in pre-filtration.

- Both membranes utilize similar three-layer construction, although the materials used differ.

Reverse Osmosis Membrane Material and Construction – What Are RO Membranes Made of?

So, what are reverse osmosis membranes made of?

As far as materials are concerned, the majority of commercially manufactured RO membranes are either made from polyamide or cellulose acetate.

- Aromatic polyamide (PA) membranes are also frequently called thin-film composite (TFC) membranes.

- Cellulose acetate (CA) membranes are also referred to as CTA membranes which stands for “cellulose triacetate”.

Both use three-layer structures, comprised of a top layer of ultrathin film – this is the actual barrier that rejects contaminants – a thicker microporous polymeric support layer, and finally an even thicker reinforcing fabric.

In CTA membranes, the top two layers are constructed from different types of the same CA polymer. In TFC membranes, these layers are constructed from different materials – polyamide for the ultrafine film, and polysulfone for the microporous support layer.

CTA membranes have a smoother surface material with very little electrical charge compared to TFC membranes. This makes them less susceptible to fouling.

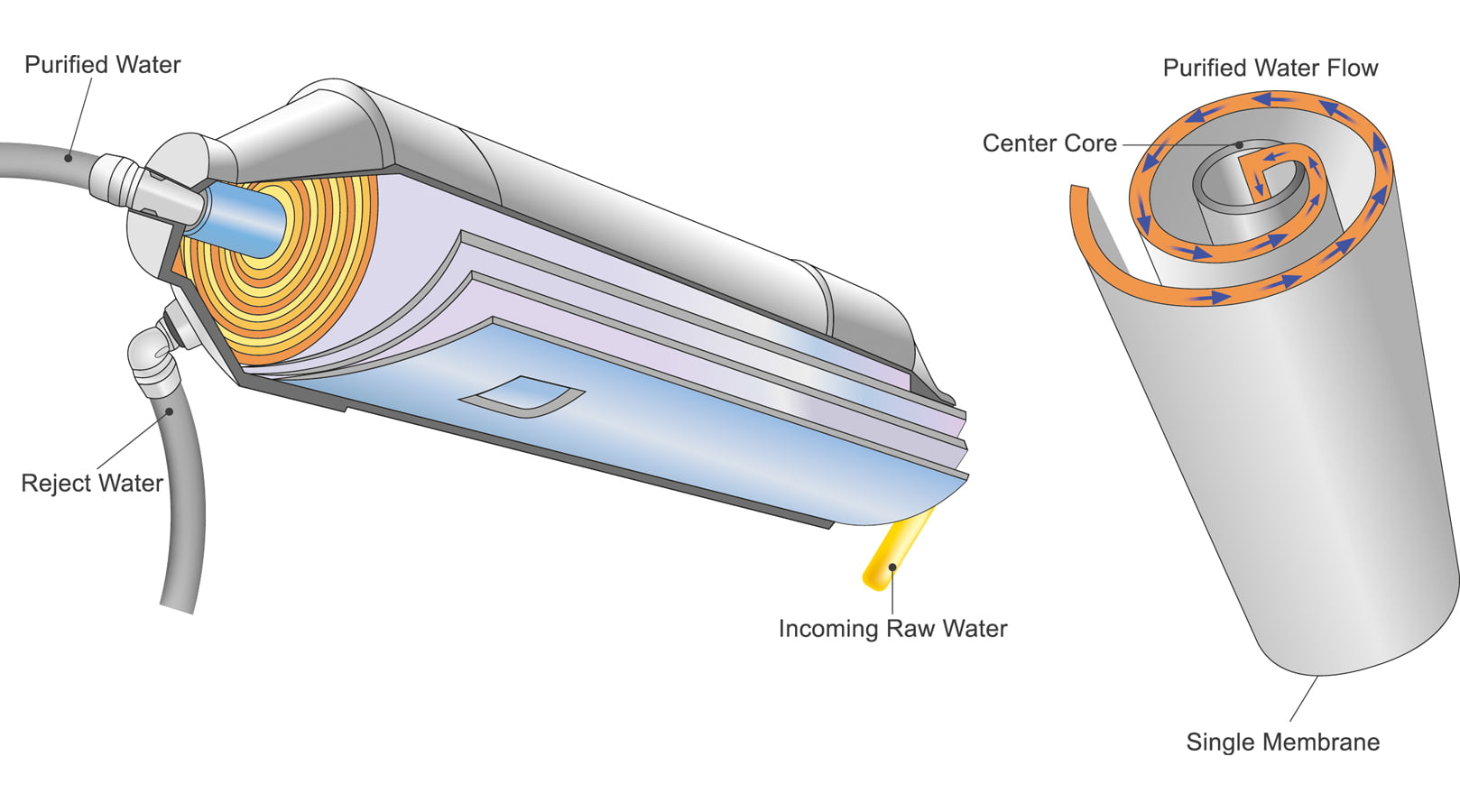

Reverse osmosis membranes can be further divided into three groups depending on their actual configuration: Spiral-wound, hollow-fiber, and tubular.

- Spiral-wound membranes are made from several flat sheets of semi-permeable material wound around a plastic tube in a spiral configuration. This creates an element containing multiple layers and a high surface area which is ideal for large-scale applications. Nonetheless, spiral-wound RO membranes are also what we find in reverse osmosis systems for home use.

- Hollow fiber membranes contain thousands of tiny capillaries packed into a small space. They have an even greater surface area than spiral-wound membranes, and although they are very small in diameter, the design is thick-walled and self-supporting.

- Tubular membranes use thin tubular polymeric elements with ultra-fine pores. Because of their ultra-fine membrane size, they produce an exceptionally pure permeate, but have a reduced capacity and can only be used in low-flow operations.

Cellulose Acetate RO Membranes

Cellulose acetate membranes are less costly, but also less effective than thin-film composite membranes. They have several limitations when compared to thin film, but can be just as effective providing the source water conditions are suited to them.

CTA membranes can only perform within a narrow pH range of 4 to 6 and temperatures between 41° and 95° F. They also have less natural resistance to bacteria than thin-film membranes and can be destroyed by certain bacteria present in surface waters.

That said, cellulose acetate membranes do have several advantages over their thin-film counterparts. They are resistant to small concentrations of chlorine (3 to 4 ppm), which means they can be used safely with moderate chlorine in the feed water. This has the effect of reducing or eliminating bacterial growth and allowing residual chlorine to prevent re-growth throughout the rest of the system.

CTA membranes also require less frequent cleaning because of reduced rates of membrane fouling due to microbial growth on the surface.

Thin-Film Composite (Aromatic Polyamide) RO Membranes

The second commonly used membrane material is thin-film composite.

TFC membranes are the most widely used RO membrane type throughout both industrial and home filtration systems. They operate at lower pressures and have better productivity than their CTA counterparts. They also allow lower salt concentrations to pass through the filter and into the final product.

Another major distinction between the two membrane types is the level of iron allowed in the feed water. TFC membranes will only function with concentrations of 0.1 ppm, compared to CTA membranes which can handle up to 1 ppm. If your feed water is higher in iron, then you may need to add an iron removal pre-filter to deal with this.

Lastly, TFC membranes can operate over a wider temperature (41° and 113° F) and pH (2 to 11) range. This gives you more versatility in the feed water characteristics in which your system can operate effectively.

How the 2 Common Types of Reverse Osmosis Membranes Operate

Reverse osmosis systems function similarly regardless of the type of membrane used, although there are minor differences.

First, feed water is passed through a series of pre-filters to remove contaminants that can harm the RO membrane – namely sediment and chlorine. Sediment and other larger particles can clog up the membrane prematurely, while choline/chloramine can damage the thin-film structure and irreversibly reduce the membrane’s salt reduction capability.

As mentioned previously, CTA membranes are more resistant to chlorine in the feed water, so there is less of a need for complete chlorine removal.

After pre-filtration, water flows into the RO membrane module. It flows across the surface of the membrane from one end. Due to high pressure, water molecules start to diffuse through the membrane and into the plastic tube in the middle unencumbered, whereas most impurities are rejected due to their larger size. Finally, the clean water flows out of the membrane housing and into the RO tank or next filter stage, whereas the leftover water carries all the contaminants down the drain.

RO Membrane Diagram

Here you can see how the RO membrane uses its multiple layers to separate contaminants from pure water molecules.

If you have any questions about RO membrane material please don’t hesitate to leave a comment below!

Information provided on BOS is for educational purposes only. The products and services we review may not be right for your individual circumstances.

We adhere to strict editorial guidelines. Rest assured, the opinions expressed have not been provided, reviewed, or otherwise endorsed by our partners – they are unbiased, independent, and the author’s alone. Our licensed experts fact-check all content for accuracy. It is accurate as of the date posted and to the best of our knowledge.