How to Size a Water Softener to Fit Your Needs (+ Sizing Calculator)

Written by: Gene Fitzgerald // Last Updated: Sep 27, 2022

This page may contain affiliate links. If you buy a product or service through such a link we earn a commission at no extra cost to you. Learn more.

Water softeners are sold in different sizes indicating how many hardness grains they can remove before they need to regenerate.

Choosing the right size is important because a softener that is too small will exhaust its softening capacity ahead of schedule, reduce water pressure and flow rate, require more time and money to maintain, and wear out prematurely.

On the other hand, a system that is too big is not only expensive to buy, infrequent regeneration cycles will also cause damage to its resin bed.

Simply put, properly sizing a water softener is key. How do you do that? Check out the following article to learn all you need to know.

Key Takeaways

This is how to size a water softener to fit your needs:

- Determine your water hardness level

- Estimate your daily water consumption

- Calculate your required daily softening capacity

- Calculate your required total grain capacity between 2 regeneration cycles

- Take into account salt efficiency

What Size Water Softener Do I Need?

5 steps are involved in properly sizing a water softener:

- Determining your water hardness level

- Estimating your daily water consumption

- Calculating your daily softening requirement

- Calculating your required total grain capacity

- Taking into account salt efficiency

We will discuss each step in detail and provide you with plenty of examples along the way so everything is easy to understand.

When you are done reading you can size your own water softener using our in-house calculator. Then make sure to check out our water softener reviews for the best systems on the market.

1. Determining Your Water Hardness Level

Please note: Knowing your water’s exact hardness level is crucial. Mere guessing will likely result in improper sizing.

Let’s start by defining what water hardness actually is:

Water classifies as “soft”, “moderately hard”, “hard”, etc. depending on its calcium carbonate concentration. Levels are measured in ppm (parts per million), mg/L or gpg (grains per gallon). The latter is the industry standard.

If you want to convert from ppm or mg/L to gpg, divide by 17.12.

1 ppm = 1 mg/L and 1 gpg ≈ 17.12 ppm = 17.12 mg/L

Hardness Chart

| Classification | mg/L | ppm | gpg |

|---|---|---|---|

| Soft | 0 – 60 | 0 – 60 | 0 – 3.5 |

| Moderately hard | 61 – 120 | 61 – 120 | 3.56 – 7.01 |

| Hard | 121 – 180 | 121 – 180 | 7.06 – 10.51 |

| Very hard | >180 | >180 | >10.51 |

How can you find out what hardness level you are dealing with? That’s simple! You have a couple different options:

- Test your water and measure calcium levels yourself. Test kits are widely available online for less than $20 USD.

- You can have your water tested at an independent laboratory (not by someone who is trying to sell you anything in your living room).

- Request a free quality report from your local supplier (not possible if you are on a private well). Usually, past reports can also be found online. Or simply call the company and ask.

Furthermore, you have to pay attention to high iron levels, particularly if you receive water from a well. For each 1 ppm of iron, add 4 gpg to the total hardness value. Some experts also recommend adding 4 gpg per 1 ppm of manganese.

Calculation Example: Hardness Measured at 140 ppm, Iron at 1 ppm

140 ppm / 17.12 = 8.18 gpg

8.18 gpg + 4 gpg (equals iron at 1 ppm) = 12.18 gpg (total hardness)

2. Estimating Your Daily Water Consumption

Step 2 is to estimate your family’s daily water consumption. If you want to take out all the guesswork you should consult your latest water bill. It’ll list your consumption within a certain time period – think month, quarter or year. Use this number to calculate the daily average.

What you can do if you don’t have access to this information is to multiply the number of people living in your home by 80 to 100. This is how many gallons of water the USGS estimates a person uses per day. If you like to take really long showers, multiply by 100. If you try to conserve water as best you can, multiply by 80.

Calculation Example 1: 36,000 Gallons Usage in Q4 2018

36,000 gallons / 90 days = 400 gallons (per day)

Calculation Example 2: 4-Person Family, 90 Daily Gallons Per Person

4 persons x 90 gallons/person = 360 gallons (per day)

3. Calculating Your Daily Softening Requirement

Lastly, multiply your hardness level by your daily water usage. The result is your daily softening requirement, so how many hardness grains a softener has to remove from your water on a daily basis.

Calculation Example: Water at 10 gpg, 360 Gallons Per Day

10 hardness grains/gallon x 360 gallons/day = 3,600 hardness grains (per day)

As you can tell from the calculation example, if your water measures at 10 gpg and you use 360 gallons a day then your potential new softener would need to remove 3,600 hardness grains each day – so far, so good.

4. Calculating Your Required Total Grain Capacity

Now, a water softener can only remove so many hardness grains before it has to regenerate. This has to do with how the softening process works. At some point, all resin beads inside the softening tank will be saturated, meaning that they can’t bind any more calcium or magnesium ions.

Regeneration involves washing out and draining away the accumulated minerals, and recharging the resin bed with sodium or potassium.

Most experts recommend to regenerate a softener about every six to seven days. This provides for a good balance between high softening efficiency, low wastewater production and protecting the head valve against wear. It’ll also conserve the resin protecting it against iron and sediment.

Multiplying our daily softening requirement of 3,600 grains by 7 days we get a total softening capacity of 25,200 grains:

3,600 hardness grains per day x 7 days = 25,200 grains (per week)

5. Considering Salt Efficiency

Theoretically speaking, this would allow us to regenerate a water softener with a 25,200-grain rating once a week and never run out of soft water. Why theoretically speaking? Because up to this point we haven’t taken into account salt efficiency a.k.a. brine efficiency.

Simply put, regenerating a softener’s resin bed to 100 percent requires a disproportionately high amount of salt, whereas partial regeneration is much more efficient. For instance:

In order to fully regenerate a 33,000-grain unit 14.1 lbs of salt are needed. The same model requires no more than 2.6 lbs of salt to regenerate 13,000 grains. And with 8.3 lbs of salt you could regenerate 27,600 grains.

In other words, while a 33,000-grain system can remove 33,000 hardness grains from water between two regeneration cycles, it would demand an excessive amount of salt doing so.

However, only recharging approx. 40% of the softening bed requires no more than one-fifth of the salt amount, while three-fifth of the salt would lead to roughly 84% regeneration. Obviously, this is a much cleverer way to operate a water softener.

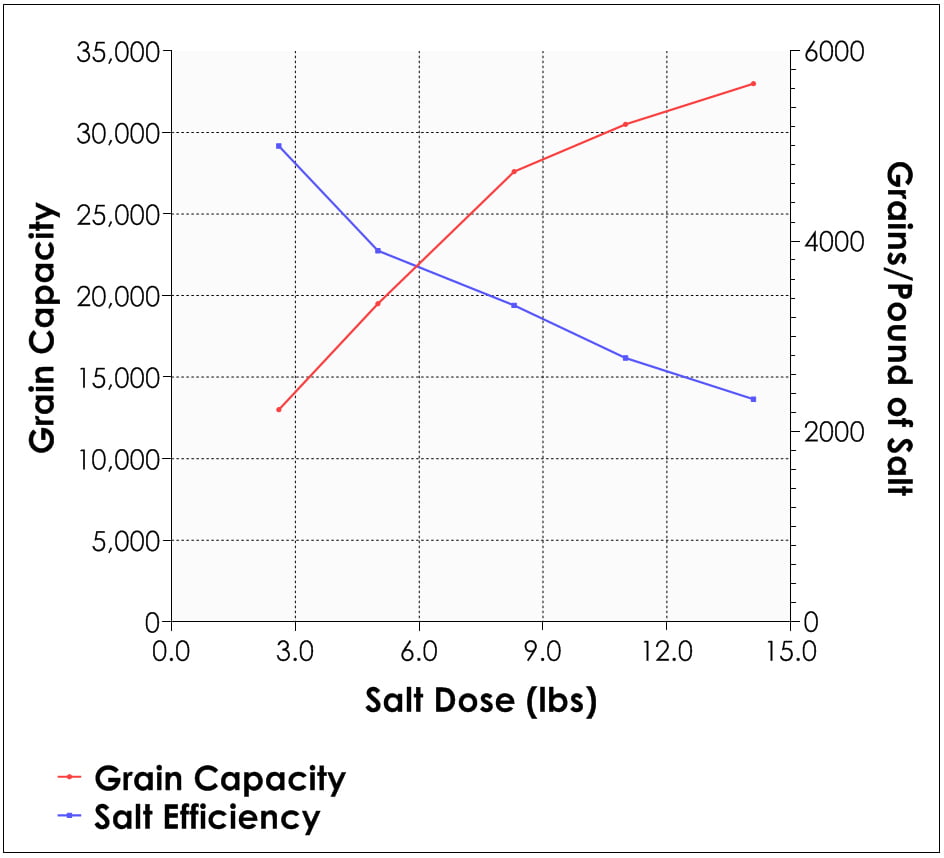

The relation between regeneration level and required salt dose is illustrated by the following chart:

The higher the salt dose, the higher the softening capacity, but the lower the efficiency per pound of salt.

Bottom line: If you require a water softener that can remove 25,200 hardness grains per week as calculated in our example above, actually choosing a system with a higher grain capacity – e.g. 40,000 grains – will save you a lot of money on salt in the long run.

What’s more, servicing will be much more convenient and less salt will be discharged into the environment threatening aquatic life. It’ll also benefit your sewage system in case you have one.

Just to clarify, the reason why you need a higher grain capacity than calculated is because if you do not let your softener regenerate to 100%, it’ll exhaust faster. This effect can be compensated by a bigger system.

Grain Capacities & Tank Sizes

A softener’s grain capacity is the maximum number of hardness grains the system can remove before it has to regenerate. The lower the rating, the higher the required regeneration frequency.

Grain capacity can also be described as cubic feet of softening resin. Higher volume means larger tank size.

| Resin in Cubic Feet | Tank Dimensions (Ø x Height) | Maximum Grain Capacity |

|---|---|---|

| 0.75 | 8″ x 44″ | 15,000 |

| 1.0 | 9″ x 48″ | 20,000 |

| 1.5 | 10″ x 54″ | 30,000 |

| 2.0 | 12″ x 52″ | 40,000 |

| 2.5 | 13″ x 52″ | 50,000 |

| 3.0 | 14″ x 65″ | 60,000 |

Grains/Pound of Salt Rating

You should always check the salt efficiency of a model which is expressed in grains per pound of salt. The number indicates how many hardness grains a softener can remove per pound of salt that it uses at the minimum salt dose and under real-life conditions.

One model might have 4,410 @ 2.9 lbs and another one 5,060 @ 2.7 lbs. The latter is more efficient. Softeners certified against NSF/ANSI Standard 44 must have a salt efficiency rating of at least 3350 grains per pound of salt so that’s something to look out for. The efficiency for systems installed in California must be at least 4000 grains per pound.

Considering Flow Rates

Daily and weekly softening capacity is all well and good, but if your softener cannot deliver enough soft water at times of peak consumption, hard water will leak through and/or you will see a drop in pressure and flow.

This can especially be the case in the morning when everyone gets up for work and school. There might be multiple showers and taps running, toilets flushing, and maybe you start the dishwasher before leaving the house.

Thus, make sure to pay attention to service flow rates measured in gallons per minute (gpm).

Generally speaking, larger homes require higher flow rates. Single households might do with 6 or 7 gpm. For families with 2 or more bathrooms we recommend a minimum flow rate of 12 gallons per minute. Big families should look for systems providing at least 15 gallons per minute. (Source)

Typical Water Use of Modern Outlets

- Faucets: 1.0 gpm

- Toilet: 3.0 gpf (gallons per flush)

- Shower: 2.0 – 2.5 gpm

- Dishwasher: 6.0 – 16.0 gpl (gallons per load)

- Washing Machine: 25.0 gpl (gallons per load)

Sizing Commercial Softeners

There are many variables that go into sizing a commercial water softener. Water temperature, pressure and flow rate are only some of them.

However, this sizing guide is aimed at private home owners. For sophisticated commercial water softener sizing and configuration we recommend you contact a specialist in your area. Just know that this is not going to be cheap.

Do you now know what grain capacity you need? Great! Click here to find our reviews of suitable systems.

If you have any questions or thoughts about how to size a water softener please don’t hesitate to leave a comment below!

Information provided on BOS is for educational purposes only. The products and services we review may not be right for your individual circumstances.

We adhere to strict editorial guidelines. Rest assured, the opinions expressed have not been provided, reviewed, or otherwise endorsed by our partners – they are unbiased, independent, and the author’s alone. We fact-check all content for accuracy. It is accurate as of the date posted and to the best of our knowledge.