Reverse Osmosis System Not Producing Enough Water? Fixes Here!

Written by: Alexandra Uta // Last Updated: Sep 15, 2023

This page may contain affiliate links. If you buy a product or service through such a link we earn a commission at no extra cost to you. Learn more.

A common issue with reverse osmosis is a system that stops producing enough water.

There are several possible causes for an RO system not producing sufficient water. Many of these are relatively easy to fix on your own, while others require more complex repairs.

If your system used to fill up glasses in seconds, and now takes minutes, read on for detailed explanations and solutions.

Key Takeaways

Reverse osmosis systems can stop producing enough water for several reasons. Some of the common causes are

- a partially closed feed water valve,

- a partially closed tank valve,

- problems with tank pressure,

- a ruptured air bladder,

- excessive water usage,

- a clogged membrane or filter,

- low feed water pressure,

- cold feed water,

- a bad flow restrictor,

- a bad ASO valve,

- kinked tubing,

- poor quality feed water,

- and no power to your pressure pump.

Many of the above issues can be solved on your own with a little DIY, while some will require more complex repairs (see below).

Reasons for Your Reverse Osmosis System Not Producing Enough Water + Easy Fixes

So, what are the reasons for a reverse osmosis system not producing enough water and how can you fix them?

Feed Water Valve Is Partially Closed

One of the easier issues to remedy is a feed water valve that’s partially turned off. The feed water valve is the valve that connects the cold water supply under your sink with the RO system.

If you’ve shut off the feed water valve to change filters or perform other maintenance tasks, you may have only partially reopened it. This leads to a low flow rate that slows down the entire system.

To fix this issue, simply locate the feed water valve, and turn it until it’s completely opened. If your system starts working again, you’ve found the source of your problem.

RO Storage Tank Valve Is Partially Closed

A partially closed storage tank valve is a similar issue to the issue above but involves the tank valve instead of the feed water valve. The tank valve is located on top of the storage tank and controls the flow of water in and out of the tank.

If you’ve recently performed maintenance on the storage tank, there’s a chance the valve hasn’t been properly reopened. Locate the valve, open it fully, and wait for the tank to refill before testing the flow by opening the faucet.

Issue with Storage Tank Pressure

RO storage tanks require a specific pressure range – generally 6 to 8 psi when empty – to work correctly. Pressure is required to send water from the tank up to the RO faucet, as well as to trigger the auto-shutoff valve to start/stop filtering water.

Over time, the tank can lose pressure, which results in poor flow from the tank to the faucet. If the tank pressure is too high, which can happen if you overpressurize the tank, the tank won’t be able to fill with water completely.

The solution to both of these issues is resetting the pressure inside the tank. To do this, follow these steps:

- Turn off the feed water valve supplying water to the system.

- Open the RO faucet and allow the water to drain completely.

- Remove the tank from the system by disconnecting the tubing connections leading to the tank.

- Take the tank outdoors or somewhere else with sufficient drainage.

- Open the tank valve on top of the storage tank. Allow the water to flow until no more comes out.

- Now, attach a bicycle pump or air compressor to the pressure valve and pump out whatever water is left.

- Use a pressure gauge on the tank’s pressure valve to check the pressure level.

- If the pressure is too low, add pressure slowly using a bike pump or an air compressor.

- If the pressure is too high, lower the pressure by depressing the pin inside the valve using the gauge or another small tool.

- Now, test the pressure level again to ensure it’s within the ideal range.

A Ruptured Air Bladder

RO storage tanks use rubber air bladders to regulate internal pressure. After repeated use, these air bladders can eventually rupture.

When this happens, the tank will still fill with water as normal, but won’t be able to send sufficient water up to the RO faucet.

To determine whether your air bladder is ruptured, simply repressurize the tank using the process outlined above. Then reconnect the tank to the system, allow the tank to refill, and then turn on the RO faucet. If the system can only pour one or two glasses of water before slowing down to a dribble, then you can be confident your air bladder is ruptured.

Unfortunately, there is no way to repair a ruptured air bladder. You’ll need to replace the tank with a new one to get the system working again.

You Need to Wait (High Water Usage)

RO systems are particularly slow at filtering water, which is why they incorporate storage tanks to keep a reserve of water on hand. Once you completely drain the storage tank, the system won’t be able to filter water fast enough to provide a decent flow rate through the faucet.

This can happen if you use an unusually high level of water, which drains the tank entirely. It can also occur if you’ve recently installed your RO system and haven’t allowed enough time for the system to process sufficient water.

This is completely normal and not a cause for concern. All you need to do in this situation is wait for the system to filter more water before dispensing. If you find this situation happening often, you might want to consider upgrading your system to a larger tank.

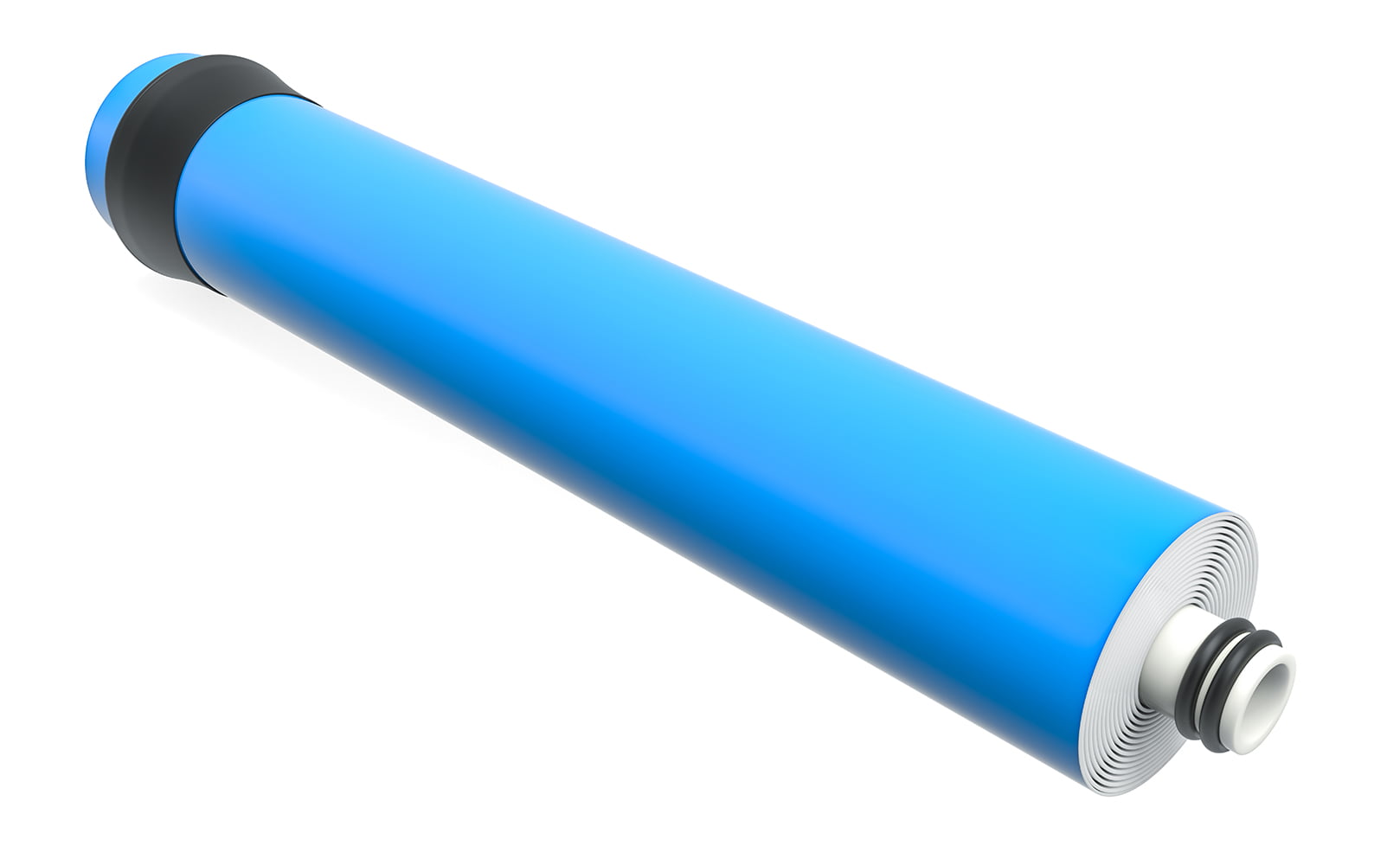

Clogged RO Membrane

RO membranes will eventually become clogged over time. That’s why they must be replaced according to the manufacturer’s schedule.

A clogged reverse osmosis membrane will result in sluggish flow through the remainder of the system, which means your system won’t be producing enough water.

To fix this, simply replace the old RO membrane with a new one and be sure to replace it according to the manufacturer’s recommendations going forward.

Clogged Filter Element

In addition to a clogged RO membrane, clogged pre and post-filters can also slow down the water flow through your system.

If you suspect that one of your filter elements is clogged, simply turn off your feed valve, drain the system, and replace the filter element in question. If your system begins running normally, you’ve found the cause of your problem.

Once again, be sure to replace the pre and post-filters on time going forward. This is typically required every 6 to 12 months.

Low or Fluctuating Feed Water Pressure

RO systems require sufficient water pressure to work properly. If the water pressure entering the system is too low, there won’t be enough pressure to force water through the RO membrane.

This results in excessive water flowing down the drain line, and little to no flow to the rest of the system.

To fix this, you can install a booster pump to increase the water pressure entering the system.

Feed Water Is Too Cold

While not a particularly common issue, if your feed water is too cold, it will lead to a slower overall system operation. If you live in a very cold climate or your home doesn’t have sufficient insulation, then you might run into this problem.

To fix this, you can either install a booster pump to compensate for the lower flow through the system or add some form of heating/insulation to the main water supply line to your home.

Bad Flow Restrictor

The flow restrictor, as the name suggests, restricts the flow of wastewater down your system’s drain line. This is needed to maintain enough pressure inside the RO membrane for it to work properly.

A bad flow restrictor will result in excessive water flowing down the drain line, with only small quantities of water making it through the membrane and onto the RO faucet.

To fix this, you’ll need to replace the faulty flow restrictor with a new one. The process differs from one system to another, so consult the documentation that comes with your system for details.

Bad ASO Valve

The ASO valve is the valve that triggers when the water is removed from the storage tank or when the tank is full. It tells the system when to start and stop filtering water based on how much water is in the tank.

If the valve is bad, your system may not produce enough water.

If the valve gets stuck in the ‘closed’ position, water won’t be able to enter the reverse osmosis system – eventually causing little to no water to flow out of the faucet. To fix this, simply disconnect the valve to release pressure and then reconnect it.

If the valve is faulty, the system won’t stop filtering water when the tank is full. This leads to constant water filtration – and a lot of wasted water. In this instance, you’ll need to replace the broken valve with a new one.

Kinked Tubing

Kinks in the tubing lines running between the various filter stages and components can lead to slowdowns in the system flow. This typically occurs when the lengths of tubing are too long – making them prone to forming kinks.

To fix this issue, simply locate the kink in the line, shut off the feed water valve, and remove the tubing section. Then use tube cutters or a utility knife to cut the section of line to the correct length or replace it with a shorter new one.

Poor Feed Water Quality

If the feed water entering your system contains high levels of contaminants, your filter elements and membrane will clog much faster than normal. While RO systems are highly effective, they have trouble dealing with elevated levels of certain contaminants such as iron or water hardness.

If your filters and membrane clog much faster than normal, you may want to get your water professionally tested. This will give you detailed information on the impurities contained in your water and their quantities.

If needed, you can install extra pre-filters to deal with these problematic contaminants before they reach the RO membrane.

There’s an Issue with the Power Supply of the Pressure Pump

If your system uses a pump to increase the feed water pressure, or some other component requiring power, then problems with the power supply might be affecting the system’s performance.

If the power supply is simply unplugged, then all that’s needed is to plug it back in. Alternatively, if the power supply is malfunctioning, you’ll need to replace it to get the system working again.

How Does an RO System Work?

Reverse osmosis systems utilize water pressure to push water through an ultra-fine membrane. The membrane separates contaminant particles from pure, clean water and sends the contaminants down the drain in the form of wastewater.

As reverse osmosis membranes use incredibly fine mesh, they can remove contaminants down to just .0001 microns in size. As a result, they’ll remove heavy metals, microbial contaminants, asbestos, minerals, salts, and much more.

While they are highly effective filters, RO membranes can’t remove everything. They have specific problems with dissolved gases like chlorine, which is why these contaminants are removed by pre-filters before they can reach the membrane.

How a Reverse Osmosis Storage Tank Operates

Reverse osmosis systems use storage tanks to keep a store of filtered water available for use at all times. This is necessary as RO filtration is a very slow process.

RO storage tanks are pressurized to operate with the rest of the system. They feature rubber bladders that separate an internal air and water chamber. When water enters the tank, the water chamber fills, compressing the air chamber, and increasing the tank’s internal pressure.

The tank’s internal pressure has a second function – controlling the system by telling it when to start and stop filtering water. This occurs through the auto-shutoff valve – which is the valve that triggers when water leaves the tank or when the tank is full.

If you have any questions about your RO system not producing enough water please don’t hesitate to leave a comment below!

Information provided on BOS is for educational purposes only. The products and services we review may not be right for your individual circumstances.

We adhere to strict editorial guidelines. Rest assured, the opinions expressed have not been provided, reviewed, or otherwise endorsed by our partners – they are unbiased, independent, and the author’s alone. Our licensed experts fact-check all content for accuracy. It is accurate as of the date posted and to the best of our knowledge.