The Different Types of RO Membranes for Home Use

Written by: Gene Fitzgerald // Last Updated: Mar 14, 2023

This page may contain affiliate links. If you buy a product or service through such a link we earn a commission at no extra cost to you. Learn more.

Several types of RO membranes are available on the market today, each designed with specific applications in mind.

Not only are they made from different materials and come in various shapes and sizes, but they also vary in their ability to remove specific contaminants.

Today we will take a closer look at the different types of RO membranes for home use.

Key Takeaways

- There are two main types of RO membranes for home use, thin film composite (TFC), and cellulose triacetate (CTA).

- TFCs are the main ones found in point-of-use RO systems due to their superior salt reduction and flow rates.

- Which kind of membrane you need depends on what you are using it for. There are various ones for home use, industrial use, brackish water use, and desalination.

The Different Types of RO Membranes

There are two main types of RO membranes for home use: Thin-film composite (TFC), also sometimes referred to as polyamide composite (PA) membranes, and cellulose triacetate (CTA).

Thin-film composite membranes are the most commonly used in residential RO systems. They are composed of an acrylic copolymer reinforced with a microporous layer. These membranes offer superior performance in salt rejection compared to CTA membranes, however they are more susceptible to chlorine.

CTA membranes are made from plasticized cellulose acetate. As mentioned, these are more resistant to chlorine, plus they are more affordable and thus often used for larger water treatment systems, even industrial applications.

Low Pressure RO Membranes (for Regular Home Water)

Low-pressure RO membranes are usually used for home water reverse osmosis filtration. There are the two main types, thin film composite (TFC) and cellulose triacetate (CTA), and each has subtypes.

While TFCs are the better filter of the two, chlorine can more easily damage them. This is why having a functioning carbon pre-filter in your reverse osmosis system is an absolute must to remove the chlorine before it reaches a TFC RO membrane.

Comparing the Characteristics of TFC vs CTA RO Membranes

A comparison of the two types of RO membranes for home use shows clear differences between them. TFC membranes are more expensive and less resistant to chlorine, but they have a higher rejection rate of overall TDS than the cheaper, more chlorine-resistant CTA membranes.

There is also a significant difference in the iron allowed in the feed water, with CTA reverse osmosis membranes allowing much more. If your water is high in iron, and you want to go with a TFC membrane, you may need to consider an iron removal pre-filter.

| Parameters | Cellulose Triacetate RO Membranes (CTA) | Thin-Film Composite RO Membranes (TFC) |

|---|---|---|

| Cost | Medium | High |

| Water pH Range | 4-9 | 2-11 |

| Water Temperature Range | 41-95°C | 41-113°C |

| Resistance to Bacteria | Good | Great |

| Max Chlorine Level | 3-4 ppm | 0.1 ppm |

| Max Iron Level | 1 ppm | 0.1 ppm |

| Salt Rejection | Around 94% | Around 96% |

| Flow Rate | Lower | Higher |

Commercial/Industrial RO Membranes

Commercial/industrial RO membranes are designed with a higher level of use in mind. Think food processing, restaurants, hotels, and hospitals. They are able to support high flows with a high permeate production rate.

Brackish Water RO Membranes

Brackish water RO membranes are designed with salty water in mind. They have a high rejection and flow rate and are designed with resilience in mind for pressure drops and spikes in feed water. They are used in any industrial application that involves removing excess salt, metals, and other TDS from water.

Seawater RO Membranes

Used for seawater desalination, these high productivity membranes are usually found on ships as well as land and sea-based desalination plants, creating drinkable water from seawater.

RO Membranes Also Come in Different Shapes and Sizes

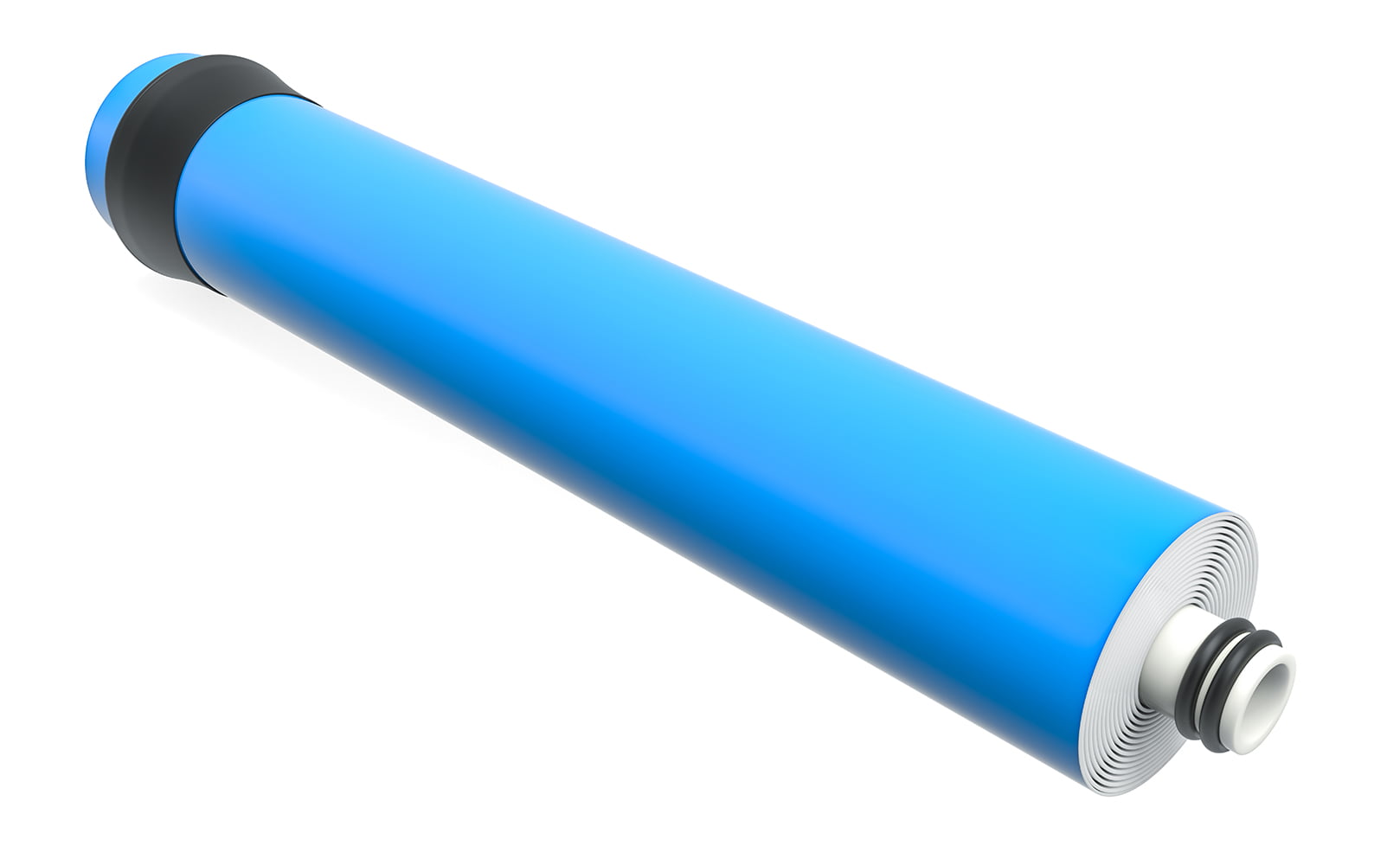

A Reverse osmosis membrane’s size and shape IS dictated by the specific application it is being used for. For instance, larger membranes may be used if a system requires a high amount of water production. On the other hand, specific applications may require a smaller membrane to fit into tight spaces. The most common types of RO membranes are spiral-wound, hollow-fiber, and tubular.

Spiral-wound RO membranes are composed of several flat sheets of semi-permeable material which are wound around a plastic tube in a spiral pattern to create a cylindrical element containing multiple layers. This ensures they have high surface area while occupying minimal space, making them ideal for large water production applications.

Hollow-fiber RO membranes have thousands of tiny capillaries that provide an even greater surface area than the spiral-wound configuration for efficient water production and filtration performance.

Tubular RO membranes utilize thin tubular polymeric elements with microscopic pores compared to the other two membrane configurations mentioned above. This makes them highly efficient at producing ultra-pure permeate but also reduces their capacity for high flow rates due to their small inner diameter size compared to other membrane configurations. Due to this limitation, they are commonly used in low-flow rate processes.

What Is a Reverse Osmosis Membrane and How Does It Work?

A reverse osmosis membrane is a semi-permeable membrane used to remove impurities for the purpose of purifying water. The reverse osmosis process applies pressure to push contaminant-filled water through tiny pore openings in the RO membrane. Water molecules are small enough to pass through these pores, but contaminants are too large, resulting in them being trapped on one side of the membrane while pure water passes through to the other side.

What happens with said contaminants? They are flushed out of the treatment system as wastewater.

In most cases, a pre-filter or sediment filter is used before using a reverse osmosis membrane. This helps improve the performance of an RO system as well as extending its lifespan. Other pre-treatment may include water softening and iron removal.

Reverse osmosis membranes are capable of removing up to 99% of all dissolved and suspended particles from water, making them highly effective at producing clean drinking water – or water used for other applications requiring high purity – from even the most contaminated sources. Additionally, they require minimal maintenance due to their robust design and will last for several years before needing replacement.

What Contaminants Does a Reverse Osmosis Membrane Remove?

A reverse osmosis membrane removes total dissolved solids (TDS) such as nitrate, lead, arsenic, fluoride and many other salts, heavy metals, and ions as a whole. Organic compounds like pesticides and herbicides aren’t safe either. Not to mention microbes including bacteria, cysts, and even viruses. Floating particles? You bet!

If you have any questions about RO membrane types please don’t hesitate to leave a comment below!

Information provided on BOS is for educational purposes only. The products and services we review may not be right for your individual circumstances.

We adhere to strict editorial guidelines. Rest assured, the opinions expressed have not been provided, reviewed, or otherwise endorsed by our partners – they are unbiased, independent, and the author’s alone. Our licensed experts fact-check all content for accuracy. It is accurate as of the date posted and to the best of our knowledge.